From Idea to Impact: Wake Forest Engineering Seniors Take on Real-World Challenges

Each spring, the Wake Forest Department of Engineering transforms into a launchpad for ideas that are as innovative as they are impactful. Over two semesters senior students channel their classroom learning into solving complex, real-world problems through the Engineering Capstone Design Project. Guided by faculty mentors, technical experts, and community stakeholders, students design, build, and test functional prototypes aimed at improving lives, in the spirit of the University’s motto, Pro Humanitate.

This year’s ten capstone teams tackled diverse societal needs—from hospital rehab devices to drone-based wildfire response and sustainable recycling of medical waste. The program gives students a chance to move beyond theory and into the real world—engaging with users, refining designs, and iterating through challenges rooted in real-world needs.

One of this year’s projects, Mission Deacon-dition, was recognized with the 2025 Coaches’ Award for its strong execution across each phase of the design process: Discovery Design, Conceptual Design, Embodiment Design, and Detailed Design. The award honors the team’s consistent performance and the high-quality feedback they received from technical experts and design panelists.

Mission Deacon-dition: Engineering a Smarter Path to Patient Mobility

For patients recovering from trauma or surgery, staying in bed for most of the day can have serious consequences such as muscle atrophy, increased risk of infection, and delayed recovery. This physical decline, known as deconditioning, occurs when prolonged inactivity causes the body to lose strength, mobility, and endurance.

Dr. Sam Carmichael, a trauma surgeon at Atrium Health and the team’s mentor, sees it every day.

“People come into the hospital with some underlying medical conditions, and after a fall or accident, they lose even more function,” said Carmichael. “Patients in hospitals spend on average 20 out of 24 hours a day in bed, and it’s shocking how quickly someone can go from living independently to barely being able to stand. Movement is medicine, but we simply don’t have the resources to get patients moving as much as they should.”

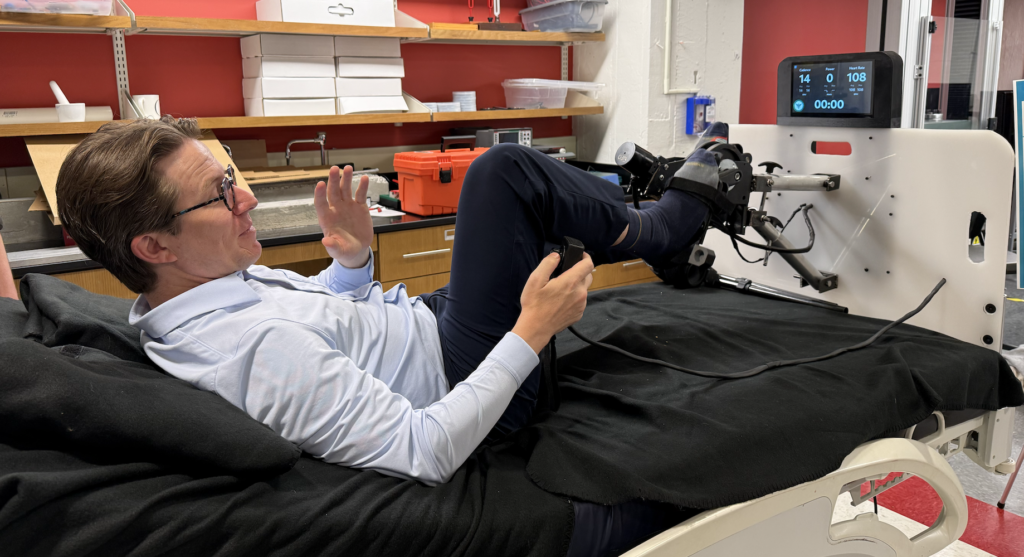

The Mission Deacon-dition team aimed to tackle this problem head-on. While capstone projects vary in terms of their starting point, with some teams beginning with an idea and building from scratch and others building on the work of previous years’ teams, this team inherited two years of prior prototypes and research. Their challenge was to evolve and improve on past work, and they did.

“This year’s team really nailed it,” said Carmichael. “They designed a compact rehab device that mounts directly into the footboard of a standard hospital bed. It doesn’t require large, bulky frames or special training to use. That’s critical because in a hospital, if it’s hard to use, no one uses it.”

The device supports both passive and active movement modes. In passive mode, a small motor initiates movement to stimulate muscle activity for patients who are too weak to exercise. In active mode, patients can engage more directly with resistance settings, supporting measurable recovery. The team also incorporated a Raspberry Pi—a compact, low-cost computer commonly used in education and prototyping—to power the system’s ability to collect and store patient activity data. This enables caregivers to monitor improvements over time and make more informed rehabilitation decisions.

“There’s a massive shortage of physical therapists,” Carmichael explained. “And every extra day someone stays in the hospital increases the risk of infection and costs to both the patient and the hospital. A solution like this, used in the ‘in-between’ times when staff aren’t available, could make a real difference.”

Wake Forest has long been a place where practical solutions to medical challenges take root. In the early 1990s, Dr. Louis Argenta, a faculty member at the School of Medicine, teamed up with biomedical engineer Dr. Michael Morykwas to develop the Vacuum-Assisted Closure (V.A.C.) device. What began as a bedside idea to help a diabetic patient with bedsores became one of the most important advances in wound healing of the past quarter-century, used on more than 10 million patients around the world.

While Mission Deacon-dition is a student project in an academic setting, Carmichael sees a parallel in its potential. The team has kept Wake Forest Innovations, which is responsible for advancing university technologies from concept to commercialization, in the loop throughout the process.

“I’m hopeful we’ll eventually be able to move forward with a pilot,” Carmichael said. “There’s such a profound need for this kind of device. There is nothing like it on the market. And we’ve seen at Wake Forest before—innovations that start small can make a global impact.”

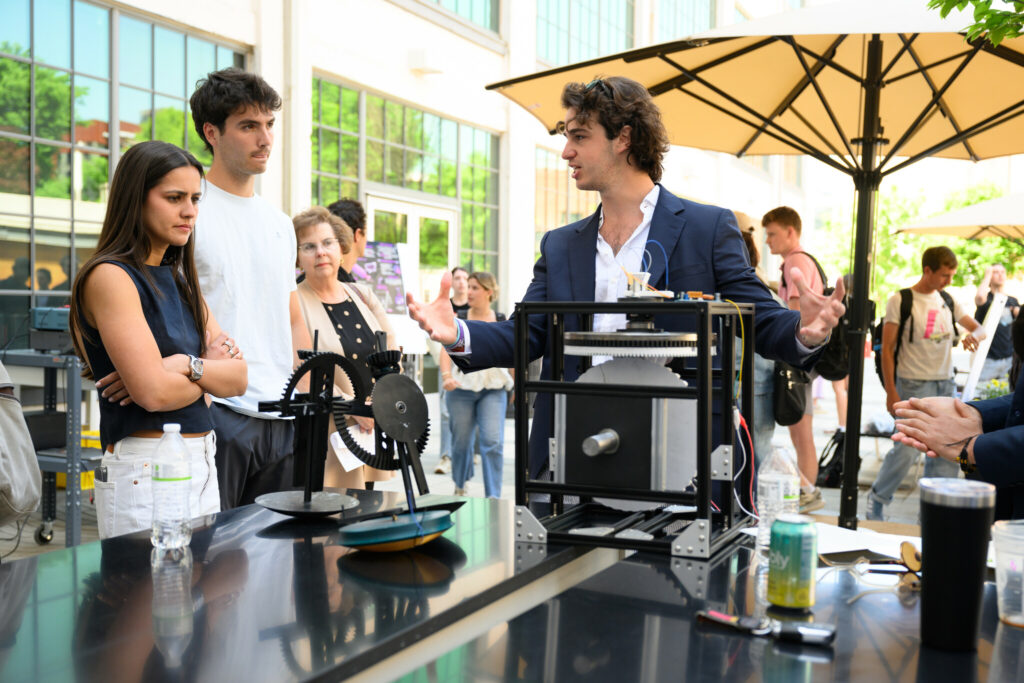

Learning by Doing: The Value of the Capstone Experience

While the technical achievements of the capstone projects are impressive, the true power of the experience lies in the process. Over the course of the year, students gain invaluable skills in engineering design, project management, leadership, and professional communication. They learn to collaborate with mentors, clients, and experts taking feedback, adapting quickly, and thinking both creatively and ethically.

“Our Capstone curriculum is focused on bridging the gap between the undergraduate Engineering curriculum and the collaborative, real-world problem-solving expected in the field,” said Dr. William Crowe who co-teaches the Capstone Design Projects. “Students tackle substantive projects with external partners, exposing them directly to industry expectations, rigorous communication demands, and the iterative reality of engineering design. This experience not only builds their technical expertise but also the confidence and critical thinking skills essential for professional success. Furthermore, in the spirit of ‘Pro Humanitate,’ many projects are designed to address community needs or contribute to a more sustainable and equitable world, allowing our students’ fresh perspectives and innovative work to deliver a real impact beyond the classroom.”

“Another key component of the capstone experience is teaming; a skill that consistently comes up when I ask employers what they are looking for when hiring engineering graduates,” said Dr. Courtney Di Vittorio who co-teaches with Crowe. “We have integrated teaming skills throughout the curriculum, starting in their first year courses, and in capstone, we emphasize how critical they are to a project’s success. Throughout the year, students practice giving and receiving feedback to each other on individual contributions and identify growth opportunities. I always remind my students that they will encounter dysfunctional teams throughout their careers, but that they can follow this process to get their teams back on track and create a more fun and productive work environment.”

Engineering Solutions to Societal Challenges: The 2025 Capstone Projects

In addition to Mission Deacon-dition, nine other teams took on equally ambitious projects, addressing societal needs across health care, sustainability, and emergency response. Each team dedicated over 1,600 hours to research, design, testing, and refinement—learning not just engineering skills, but how to make progress on problems that matter.

Winchcraft: Enabling drone-assisted deployment in hazardous environments

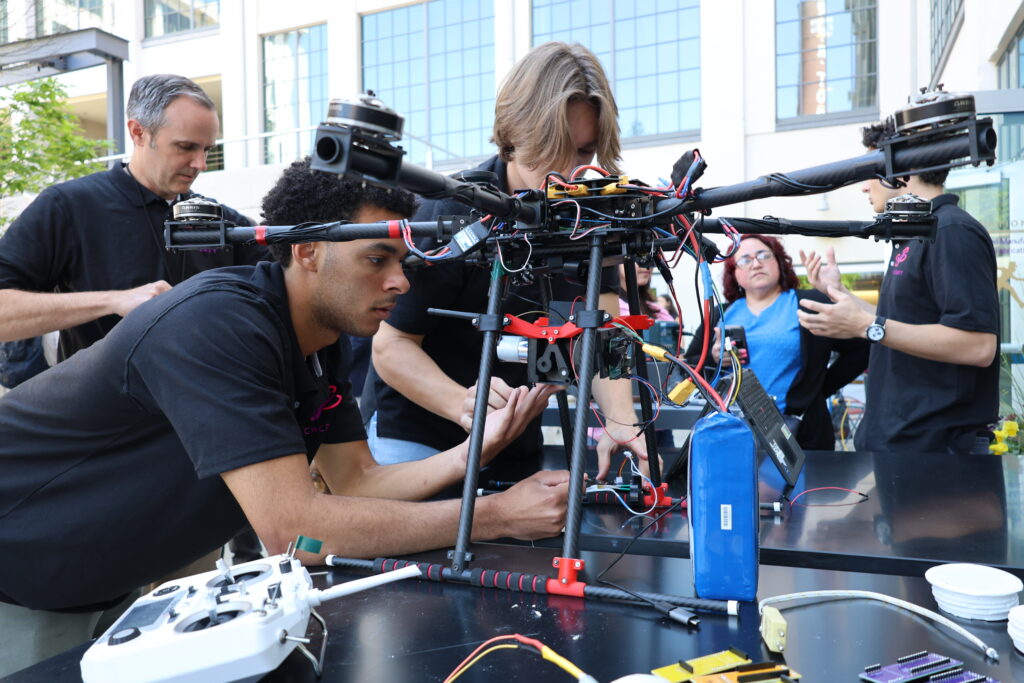

Drones are valuable tools in disaster zones, but they often lack the ability to deliver equipment or sensors directly into dangerous or hard-to-reach areas. Dr. Luthy, an engineering faculty member, works in this research space and pitched a capstone project to advance drone capabilities. The Winchcraft team set out to solve this by designing a low-cost, lightweight, modular winch system and thermal data logger that can be mounted on drones to lower payloads with precision.

Balancing payload weight, flight time, and stability, the team created a system capable of safely deploying tools like air quality sensors or small supplies from a hovering drone. Their design is adaptable across multiple drone platforms and could support applications in wildfire response, environmental monitoring, and search-and-rescue operations.

By working with public safety and environmental stakeholders, the students refined their prototype to meet real-world needs, highlighting the power of engineering to support safer, more effective field operations.

Saf-E Bike: Enhancing bicycle safety through innovative lighting

In response to the growing popularity—and growing risks—associated with e-bike use, this team designed an adaptive brake light system aimed at improving rider safety. With e-bikes often operating at higher speeds and used as primary transportation, the rate of accidents and head trauma has sharply increased. The team’s solution was a sleek, durable rear-mounted light that communicates a rider’s behavior in real time.

The final prototype features four light modes: standard riding, slow braking, hard braking, and turn signals—all controlled via a Bluetooth-connected handlebar module. The team iterated on several designs, incorporating user feedback to reduce the size, enhance weather resistance, and optimize light diffusion. The result is a compact, glass-fiber ABS casing with a red translucent lens designed for clear signaling in diverse riding conditions, day or night. The Saf-E Bike system aims to increase awareness among nearby drivers and pedestrians, supporting safer commutes and recreational rides alike.

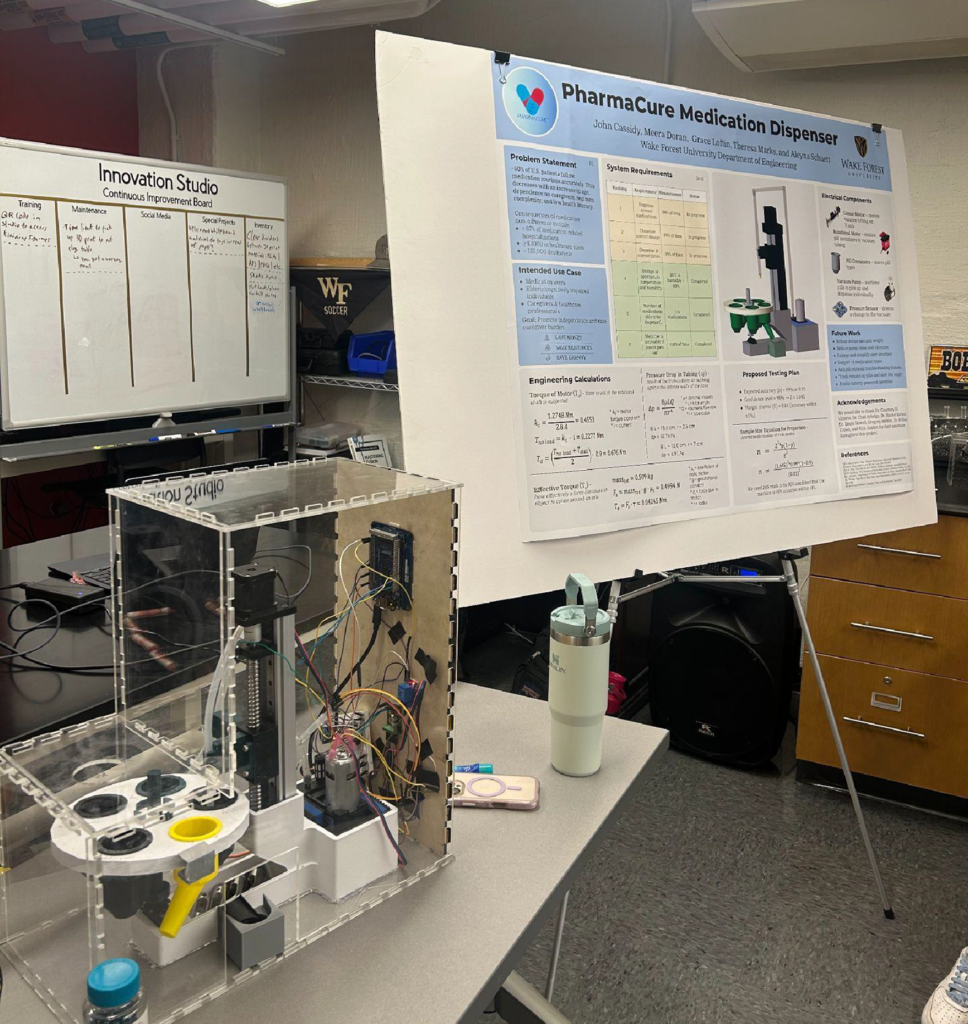

Pharmacure: Improving medication access and adherence for older adults

For many older adults, managing multiple medications can be a daily challenge, especially for those with arthritis, memory loss, or vision impairments. Mistakes in dosage or timing can lead to serious health complications. The Pharmacure team set out to design a more accessible, user-friendly way for elderly patients to take their medications safely and consistently.

Their prototype, the Pharma Pal, features an intuitive vacuum-based dispensing system that uses color-coded compartments, tactile feedback, and time-lock mechanisms to prevent missed or incorrect doses. The device was designed with both independence and safety in mind, providing users with structure while minimizing complexity.

To shape their design, the team gathered input from caregivers, pharmacists, and geriatric specialists. Their work reflects a growing need for assistive technology that helps aging populations maintain autonomy while reducing preventable medication errors.

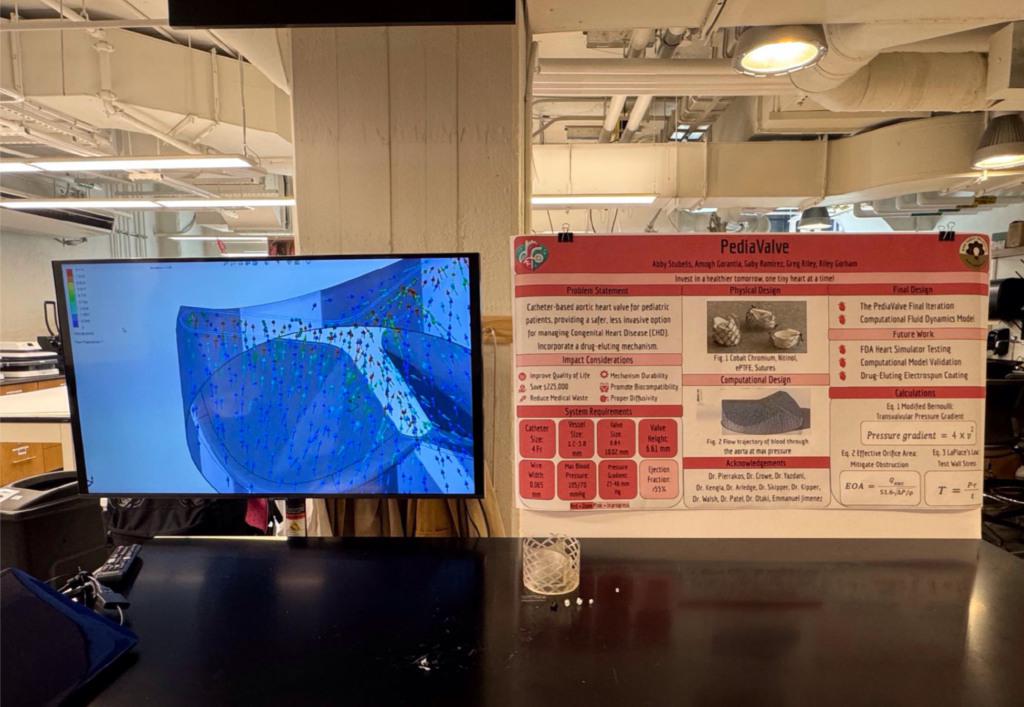

Pediavalve: Advancing pediatric heart valve design to reduce repeat surgeries

Children born with heart valve defects often face a lifetime of surgeries, as standard replacement valves don’t grow with the patient. The Pediavalve team took on this high-stakes challenge by designing a next-generation pediatric heart valve that aims to reduce the need for multiple interventions.

Building on work from previous capstone teams, this year’s group focused on improving both the scalability and durability of the valve. Their design incorporates more flexible materials and geometry that can accommodate growth, potentially extending the lifespan of the valve before replacement is needed.

With biomedical concentrations across the team, students engaged directly with physicians in the Atrium Health network and received mentorship from Dr. Olga Pierrakos, a biomedical engineering expert, as well as medical professionals including pediatric cardiologists and cardiothoracic surgeons. These collaborations informed their understanding of clinical requirements and helped them refine the design for surgical feasibility.

Though still conceptual, the team’s physical and computational prototypes represent an important step toward a long-term solution for young patients facing repeated heart surgeries, and gave students deep insight into the challenges of real-world biomedical design.

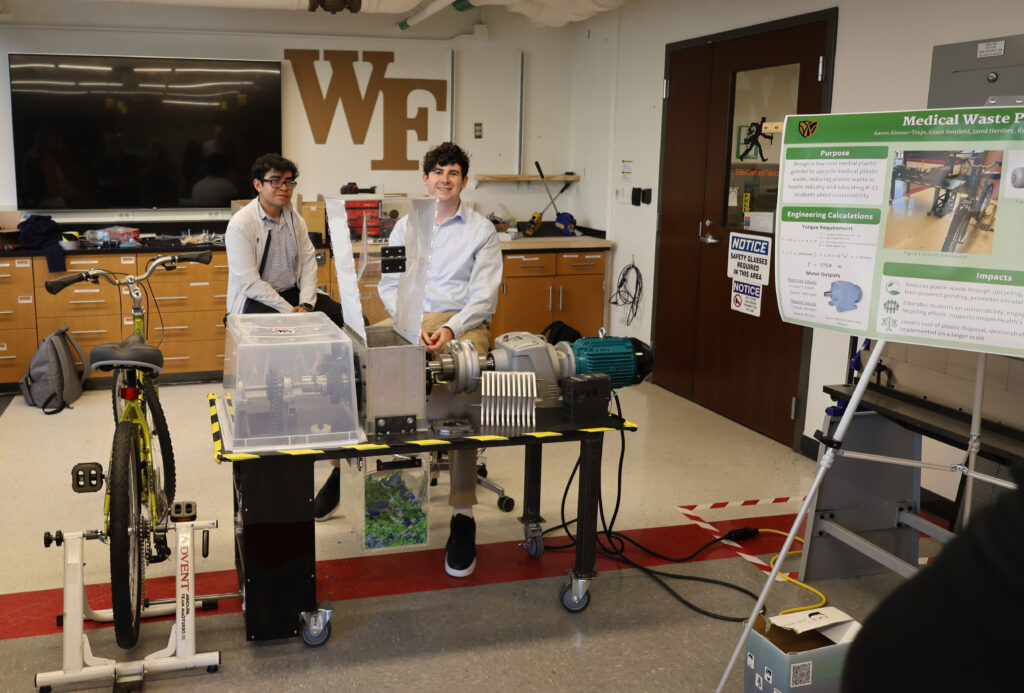

Sustainable Shredders: From hospital waste to hands-on STEM

Hospitals generate a significant amount of single-use plastic waste, from pill bottles and containers to syringes. Many of those plastics that pose no biohazard risk are still incinerated, contributing to greenhouse gas emissions and landfill waste. Dr. Alex Guevel from the biomedical engineering department at the WFU School of Medicine has been exploring innovative, community-based initiatives to reduce waste and proposed a capstone design project.

The Sustainable Shredders team designed a medical plastic waste grinder to be installed in Atrium Health’s new STEM lab in Charlotte, NC. The goal of the project was to create a hands-on educational tool that teaches students about sustainability, upcycling, and engineering.

The team developed a closed-loop system to demonstrate how that plastic could be collected, ground into flakes using a grinder powered either by a motor or a bike pedaled by students. This human-powered component helps students better understand how much energy is required to operate machinery, making energy consumption a tangible and memorable concept. The flakes produced by the grinder can be reused in 3D printing or injection molding to create new medical tools that could be cycled back into hospital use.

The team’s prototype includes a grinder unit, dual power system, and an accessible, student-friendly chute interface. The project aligns with Atrium Health’s educational goals and sustainability mission while sparking interest in engineering, energy literacy, and environmental responsibility among future innovators.

Ocean’s Motion: Harnessing wave energy to power coastal and island communities

In many parts of the world, communities located near the ocean lack reliable access to electricity, either due to weak infrastructure or vulnerability to extreme weather. The Ocean’s Motion team set out to address this by designing a wave energy converter that transforms the natural motion of the sea into usable electrical power.

The idea for the project was originally inspired by one team member’s experiences growing up in the Philippines, where power outages in remote coastal areas are common and access to electricity is limited or inconsistent. That personal connection fueled the team’s passion to create a solution that could make a meaningful difference in similar communities around the world.

Their buoy-based system captures energy from wave oscillations and uses a mechanical system to generate electricity, which can then be stored or used for off-grid needs such as lighting, charging, or water purification. The device is designed to be low-maintenance, corrosion-resistant, and scalable for different community sizes.

By working with experts in renewable energy and marine engineering, the team accounted for the challenges of variable wave conditions and long-term exposure to saltwater environments. Their prototype emphasizes affordability, resilience, and ease of deployment—qualities critical for communities most affected by climate and infrastructure vulnerabilities.

Ocean’s Motion received the 2025 Pro Humanitate Award, a recognition of the team’s commitment to addressing a pressing global challenge through innovative, human-centered design.

Type Ship: Pushing the limits of electric propulsion through competitive boat design

Electric propulsion is one of the most exciting frontiers in sustainable transportation, including on the water. The Type Ship team took on the challenge of designing and building a high-speed electric watercraft to compete in the American Society of Naval Engineers’ Promoting Electric Propulsion (PEP) competition.

Their vessel was engineered for speed, agility, and energy efficiency. From hull design to propulsion control, the team focused on optimizing every element of the boat to perform under the rigorous demands of race conditions. That meant balancing battery weight and motor efficiency, ensuring stability at high speeds, and navigating the constraints of competition regulations.

Their hard work paid off. Type Ship placed second in the national competition—an exceptional result that showcased their technical expertise, teamwork, and on-the-fly problem solving. Dr. William Crowe praised their “design, tactical decision making, and sheer hard work in the field of electric naval propulsion.”

In addition to earning top honors at the competition, the team won both the Prototyping Award which celebrates the team that delivered high-impact and high-quality prototypes, demonstrating both thoughtful and high-quality design work and the successful implementation of those designs and the People’s Choice Award, reflecting the excitement and curiosity their project sparked among attendees.

More than a race entry, Type Ship demonstrated how Wake Engineering students can apply their skills to fast-moving, real-world challenges that mirror the innovation needs of the green energy economy.

Hydro Empower: Tapping into water infrastructure to power remote Ugandan communities

In the Rwenzori Mountains of Uganda, access to clean water and electricity remains a daily challenge. Nearly 60% of the population lacks reliable electricity, and for many, clean water sources are more than a kilometer away. To address the water issue, Wake Forest faculty member Dr. Joshua Dickenson designed a gravity flow scheme that transports filtered mountain water to local communities using a sustainable, low-maintenance system of reservoirs and pressure-regulated pipes.

The Hydro Empower team took that innovation one step further: they set out to design a way to generate electricity from the existing pressure in the gravity flow system, without compromising water quality or flow rates.

Their micro-hydropower prototype is modular, affordable, and designed to be implemented at various points in the gravity-fed pipeline. It captures energy from the excess water pressure that would otherwise be released in break pressure tanks and converts it into usable electrical power for nearby communities.

The students carefully prioritized system requirements: protecting drinking water quality, maintaining pressure for tap access, and ensuring their design could last the 20-year projected lifespan of the water system. Equally important, the device had to be built using materials that are locally available and affordable, so that community members could maintain and even replicate it without outside assistance.

By addressing two critical challenges—clean water and sustainable power—Hydro Empower exemplifies engineering in service of real people, with real constraints, and long-term impact in mind.

Truck Tecs: Automating cable winding to improve efficiency and worker safety

The Truck Tecs team partnered with Altec Inc. in Mount Airy, NC—a leading provider of products for the utility and telecommunications sectors—to improve the rope winding process for their puller tensioner trucks. These trucks are used to support power restoration during outages, which are becoming increasingly frequent and severe.

Altec’s existing manual winding process required constant brake adjustments and offered no method for measuring rope tension, leading to inefficiencies and safety risks. The Truck Tecs team designed a brake regulation system powered by a Milwaukee M18 power tool battery that uses a pressure sensor and a digital encoder to provide real-time tension feedback. An Arduino microcontroller interprets this data and adjusts the braking force via a stepper motor, maintaining optimal rope tension.

Their prototype meets OSHA and NEC standards, accommodates ropes of varying sizes, and is forklift-transportable. It improves safety and productivity while reducing physical strain on workers. The team sees the potential for broader societal impact by helping speed up power restoration efforts and minimizing the human and economic costs of outages.

These projects not only represent the culmination of students’ undergraduate education, they also launch them into the world as engineers ready to lead with purpose.

Engineering with Purpose

Each project reflects Wake Forest’s distinctive approach to engineering: collaborative, impact-driven, and deeply connected to human needs. In the words of the students, mentors, and faculty who brought these projects to life, it’s not just about what they built—it’s about who they became in the process.

To learn more about partnering with Wake Forest Engineering on future capstone projects, visit engineering.wfu.edu/engineering-capstone-project or email Dr. William Crowe.